In a general sense, the craft consisting prototyping, using

various manuals, which have the function of acting as a "model" for

industrial production. These models are typically used to obtain a mold. The

figure of the craftsman modeler is disappearing, replaced by machines that can

be provided a numerical model from a CAD system.

|

| Modelling Hobby |

The models in a common sense, is also a building consisting hobby

and eventually direct (dynamic modeling) miniature reproductions of machines,

people or buildings. Originally from the practice of certain craftsmen of

centuries past, especially furniture, to build small-scale examples of their

products, and to show them to your customers without actually building them

before receiving the order.

The

modelling as a hobby can be divided into:

Dynamic:

- Scale models that move and direct remote

control as aircraft and vehicles. Here fans seeking maneuver in the most

skilful the model and achieve maximum control develop the device.

Static:

- Scale Models in great detail whose purpose is

to observe them without moving. For amateur or professional plastic modelling

each model represents a "museum piece" creating their own

private collections that can have various themes: historical warmongering,

civil engineering, science fiction, etc.. Here fans seeking to represent

the most realistic level possible of the original model. By the latter is

incorrect to consider as toys static scale models

Rookery Modelling :

The main

rookery modelling as a hobby and the most common models are:

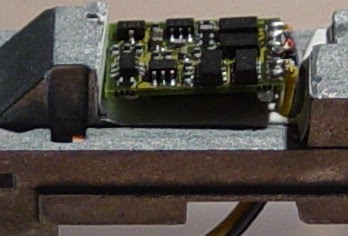

- Model Railway: Trains with movement to realistically

detailed scenarios

- Aeromodelling: Aircraft and other devices capable of flight

by a remotely controlled motor

- Automodelling: Vehicles and other ground motion artifacts

by a remotely controlled motor

- Marine Modelling: Boats and other navigation devices

capable of remote controlled motorized water

- Amateur Rocketry: Rocket launch capable

Static or

static models:

- Civil and military aviation propeller planes,

jets, helicopters and other artifacts

- Military vehicles, tanks and various weapons

- Naval and civilian models as sail boats,

aircraft carriers, destroyers, patrol, merchant ships and submarines

- Civil and racing cars